|

|

|

HARNESS SOLUTIONS - INTERCONNECT COMBINATIONS

Teledyne Storm Microwave delivers high frequency single-cable alternatives compliant with stringent environmental, mechanical, and RF performance requirements. For over 35 years, Teledyne Storm cables have been the design-in choice of program design engineers for many mission critical applications.

Our cables are selected for attributes that include phase stability with temperature change, mechanical robustness when exposed to extreme environmental conditions, extended flex-life, and low attenuation for a given cable diameter to be installed in constricted space.

TSM cable can be offered in a number of constructions related to jacket materials, center conductor, dielectric core, outer conductor, and protective braid, as well as in a range of outer diameters based on your desired RF performance compliance requirements. Phase matching of assemblies is available on request.

All of these parameters are consideration points in optimizing your cable selection to ensure system performance compliance. Our Harness Engineering Team is available to work with you early in the process to review your system goals and offer support in deciding on the RF interconnects best suited to ensure your milestones are met, and met reliably.

| Contacts |

| BODY AND CONTACT: |

Beryllium Copper per ASTM B196, C17300,

Gold plated per ASTM B488, Type 2, Class 1.27 |

| LOCKING RING: |

Beryllium Copper per ASTM B196, C17300,

Gold plated per ASTM B488, Type 2, Class 0.25 |

| INSULATOR: |

Teflon per ASTM D1710, Type 1, Grade 1, Class A |

| O-RING: |

Silicone Rubber per ASTM per A-A-59588 |

| LOCKING NUT: |

Corrosion resistant steel Per ASTM 582, S30300 Alloy,

Passivate per SAE-AMS-2700 |

|

| Connector Block |

| HOUSING |

Brass per ASTM B16, C36000 alloy, Nickel plate per SAE-AMS-QQ-N-290 |

| JACK SCREWS: |

Corrosion resistant steel |

| GASKET: |

Silicone Rubber per ASTM per A-A-59588 |

|

| Temperature |

-55° C to +125° C |

| Salt Atmosphere (Corrosion) |

Meets MIL-STD 202, Method 101, Test Condition B |

| Vibration (High Frequency) |

Meets MIL-STD-202, Method 204, Condition D |

| Shock (Specified Pulse) |

Meets MIL-STD-202, Method 213, Test Condition I |

| Ingress Protection |

IEC 60529 IP54 (1.0 mm probe/watersplash) |

| Nominal Impedance |

50 Ohms |

| Frequency |

DC � 50 GHz |

| VSWR |

Freq. Range GHz |

Mated Harness Pair |

On Board:

Edge Launch |

Vertical Launch |

|

0 - 9

9 - 18

18 - 26.5

26.5 - 40

40 - 50

|

1.20:1

1.35:1

1.35:1

1.55:1

1.55:1

|

1.30:1

1.45:1

1.45:1

1.55:1

1.60:1

|

1.35:1

1.50:1

1.67:1

1.98:1

�

|

| Cable Attenuation (Nominal) |

0.94 dB/ft @ 18 GHz |

1.17 dB/ft @ 26.5 GHz |

1.71 dB/ft @ 50 GHz |

|

| DWV (@ sea level) |

325 Vrms when tested per MIL-STD-202, Method 301 |

| Insulation Resistance |

5000 Mega Ohms minimum when tested per MIL-STD-202, Method 302, Condition B |

| RF Leakage |

70 dB thru 18 GHz; 65 dB thru 26.5 GHz; 55 dB thru 40 GHz per MIL-STD-1344,

Method 3008 (Mode Stirred) |

| Channel to Channel

Isolation (Cross Talk) |

95 dB min. thru 40 GHz (Testing at other frequencies available on request.) |

| Storm Flex® 086 Cable Outer Diameter |

0.096 inch (Nominal) |

| Minimum Bend Radius |

1.0 inch (Dynamic)

0.188 inch (Static) |

| Durability |

500 mates (Minimum) |

Electrical � SMPM Contacts

Characteristic Impedance: 50 ohms

Operating Frequency: DC to 40 GHz

VSWR:

1.25:1 TYP. DC to 26.5 GHz (Connectors Only)

1.4:1 TYP. 26.5 GHz to 40 GHz (Connectors Only)

Insertion Loss: 0.12 * √f (GHz), DC to 26.5 GHz

Isolation: > 100 dB, DC to 26.5 GHz

Operating Voltage: 200 volts AC

|

Mechanical

Axial Travel: .079" Min

Radial Float: ±.010" Min

Engage Force: 3.5 lbs (typical per contact)

Environmental

Temperature Range: -55 to 105°C

|

Click table to view PDF

Click table to view PDF

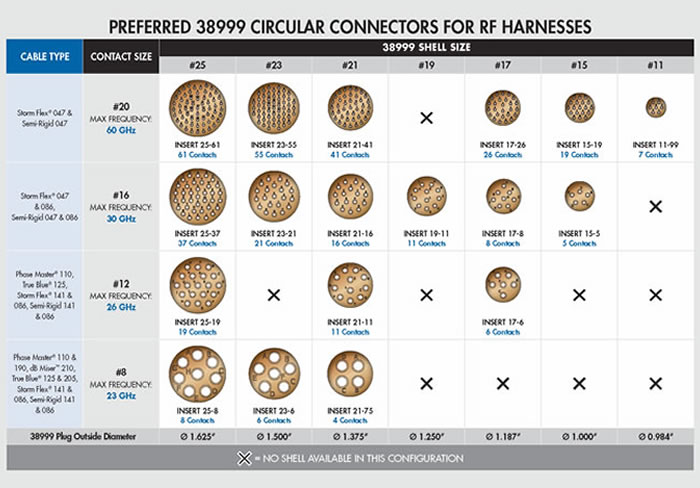

The 38999 style connector is one of the most common connectors used with harness assemblies, due to their high density and quick connect features.

These connectors not only deliver a quick disconnect capability, they offer a keying feature that prevents mismating.

Accurate mating alignment of the 38999 connector is critical, because it controls RF performance parameters such as insertion loss, return loss, and shielding effectiveness of the cables terminated with the connector.

Connector contacts are typically stainless steel and gold-plated beryllium copper, with a PTFE-based dielectric material.

Teledyne Storm has special contacts available which allow our harness assemblies to operate at frequencies much higher than the typical MIL Standard contacts allow.

Finally, the core of the connector is located within a supportive shell that is most commonly made from aluminum that is anodized or plated for corrosion protection.

Teledyne Storm has broad experience supplying Tailored Harness Solutions incorporating the 38999 style connector. This expertise in materials selection, alignment control, and the overall cable termination process ensures that our harnesses will be achieve your RF and mechanical performance requirements.

TSM delivers high frequency single-cable alternatives compliant with stringent mechanical and RF performance requirements.

The technology built into our Harness Solutions is based on over 35 years of coaxial cable design and manufacturing expertise.

TSM cables address flexibility, shielding, attenuation, shock and vibration requirements with a comprehensive range of constructions that deliver the highest levels of reliability for today�s�and tomorrow�s�applications.

The TSM cables used in building our harnesses include Storm Flex�, Phase Master�, True Blue�, and dB Miser� addressing flexibility, phase stability, durability, and low loss requirements.

Click on the images to download PDFs of the individual cable data sheets.

|

|

![]() Home

Home

![]() Company Info

Company Info

![]() Products

Products

![]() News

News

![]() Resource Center

Resource Center

![]() Careers

Careers

![]() Contact Us

Contact Us